Vatva, Ahmedabad, Gujarat

- GST NO. : 24AQRPY0664M1Z0

| Business Type | Manufacturer, Exporter, Supplier |

| Material | MS |

| Brand Name | Hexacon |

| Driven Type | Electric |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

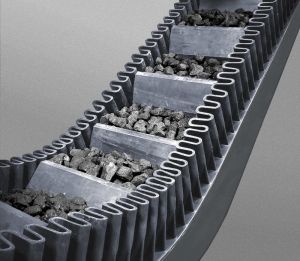

Bucket elevators are often used to raise free-flowing bulk solid materials to a higher elevation in a range of industries, including chemicals, minerals, foods, wood products and wastewater treatment. As the name implies, bulk solid materials are conveyed via buckets, which are firmly attached to a belt or chain. As shown in Figure 1, each bucket gets filled as it pushes through a pile of material at the elevator’s bottom inlet (or boot) section. The buckets then travel upwards and empty at the elevator’s top (or head) section.

Bucket elevators excel at conveying material upwards vertically, which most other mechanical conveyors struggle with, especially if the vertical distance exceeds 10 or 20 feet. Bucket elevators can be small or large and can convey over short or long vertical distances. One of the most common applications is filling silos — the material is moved to the top of the bucket elevator, where it falls out of the bucket into spouting, through which it flows by gravity into the silo.

Industrial bucket elevators are available in a few configurations. Centrifugal bucket elevators rely on centrifugal force to fling material out of the bucket as it passes over the head pully at high speed. Belt speeds of 225 to 300 feet per minute are typical, and capacities can be very high, up to 5,000 cubic feet or 150 tons of material per hour.

Continuous bucket elevators move at about half the speed of centrifugal bucket elevators, so their capacities are correspondingly lower. However, the lower speed makes them more suitable for abrasive or fragile materials. Instead of flinging material out of the bucket at the top, the slower speed allows material to fall out of the bucket by gravity right after the bucket turns over at the top. The loose material then flows past the back of the previous bucket and into the outlet chute.

Most bucket elevators are unidirectional, moving material only in the vertical direction. However, a few designs use buckets that are not rigidly attached to the belt — they swivel to remain horizontal even if the belt changes direction. The buckets are then mechanically tipped at the discharge point to empty the buckets. These elevators typically form an S- or L-shaped layout in the plant.

Bucket elevator maintenance

Bucket elevators are not maintenance-free. Wear is a factor, especially since the buckets fill by pushing through a pile of material in the bottom boot. Regular maintenance and parts replacement are needed, so it is important to ensure that critical areas at the top and bottom are easily and safely accessible.

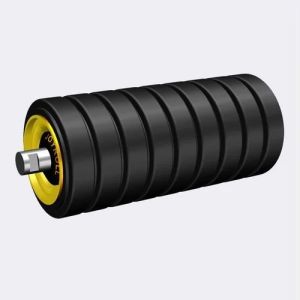

Belts and chains stretch, so an adjustment or take-up is required to maintain the correct tension. Various take-up designs are available. Frequent checks of slack or proper tension are important for reliable operation.

Moreover, economical instrumentation is available to monitor factors such as belt alignment, speed, bearing temperature, and material plugging. These can provide early warnings to greatly decrease downtime and increase safety.

Bucket elevator sizing

The capacity of a bucket elevator is a function of the bucket volume and how many buckets go past in a given time. In other words, volumetric throughput equals the volume of each bucket times the linear speed of the belt divided by the bucket spacing. Gravimetric throughput equals the volumetric throughput times the bulk density of the material.

Bucket volume is determined by the geometry of the bucket and the fill efficiency, or percent fill, during operation. Various bucket sizes are available from each manufacturer, but lengths of 6, 8, 10, 12, 14, 16, and 18 inches are common. As described earlier, belt speed is typically 225 to 500 feet per minute for a centrifugal discharge and about half that for other bucket elevators

Looking for "Bucket Elevators" ?

Explore More Products