Vatva, Ahmedabad, Gujarat

- GST NO. : 24AQRPY0664M1Z0

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Material movieing |

| Brand Name | Hexacon Enterprises |

| Finishing | Polished, Unpolished, Chrome Finish, Powder Coated |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

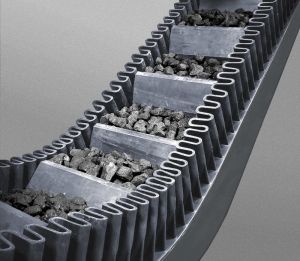

Drag chain conveyors are used for special transportation of smaller capacities. Drag chain conveyors work on the principle of a chain-and-flight combination pulling a volume of material along. The chain is equipped with different flights/paddles and drags the material from various charging points to several discharging points. The enclosed conveying device is used mainly for dusty, abrasive, or hot material and, as such, has only a very limited application in coal. However, the power plant industry and other coal industry players ask for specialized conveying systems, for which the very flexible drag chain conveyor might be a solution. Horizontal, vertical, or inclined solutions, with a possible explosion-proof and dust-tight design, might be necessary for some special applications in the coal industry.

If you took an open-ended length of bicycle chain, cleaned the oil off it and laid it on the worktop in your kitchen you would be ready to simulate a drag chain. First off, nail one end of the chain firmly to the worktop (don't try this at home) then pick up the other end and place it on top of that which is nailed down, so that the chain loops back on itself from the middle. The loose end can now be moved back and forward, sliding over the chain below and extending almost full length in one direction and then the other. If you were to embed a small electrical cable within the chain it could power a moving object and follow it up and down the worktop.

The production version of a drag chain (Fig. 9.22) is similar to the do-it-yourself version, essentially a long jointed tray carrying cables within it. The kind we are talking of here can be connected to a power supply within the CMA and laid halfway down a cave, then loop back on themselves and connect to the crane itself. It is quite a neat solution with cable furling and unfurling as a crane moves along, and is more reliable than a cable reeling system. Once again, though, it has limited use within a radioactive cave environment, mainly because drag chains are unable to contribute to a crane's recovery.

Looking for "Drag Chain Conveyor" ?

Explore More Products