Vatva, Ahmedabad, Gujarat

- GST NO. : 24AQRPY0664M1Z0

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Condition | New |

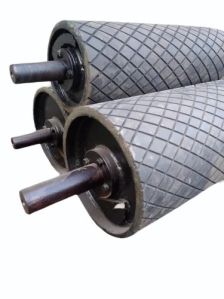

| Color | Black, Green |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

A belt conveyor system can be implemented with a very economical cost per foot of the conveyor for many warehouse and industrial applications. Because it includes just one motor and a simple belt system they are quite simple. Hence they’re often one of the first productivity improvement purchases that a growing company will make. Although there are many belt conveyor types, the simplest style is known as a slider bed style. When linked together with sensors and other automation equipment a conveyor belt system can greatly enhance productivity. The weakness for them though is that generally they are only used for transport applications. This means that the belt conveyor equipment just moves the product from point A to point B. This may be sufficient, but a belt conveyor cannot typically buffer or accumulate the parts. Nor are they typically used as a working surface for production team members. As one of the leading online belt conveyor manufacturers, Ultimation can guide you through the pros and cons of the different types of belt conveyors. We’ll also help you compare if another different type of conveyor would be a better choice. WHAT ARE THE TYPES OF CONVEYOR BELT SYSTEMS? Slider Bed Belt Conveyor Roller Bed Incline Belt – Slider Incline Belt – Roller Troughed Belt Conveyor Trough Drum conveyor belt Looking for a conveyor belt for sale? These models shown below are a small sample of the variations available from our catalog. You can download the full catalog from this page or call our team for help. BELT CONVEYOR ADVANTAGES – USE THEM TO: Move simple products from one location to another Move products up or down inclines. Check with our engineers on the highest angle for your product. We generally limit the incline of a belt style system to 25 degrees Move in either continuous or indexing modes. The belt can stop and starts each time to move a product. If you place a sensor at the end of the belt, the conveyor can stop. In other cases, packages are loaded and unloaded from a continuously running belt Use when changing the speed is necessary. We can add a VFD (variable frequency drive) for speed control. This works by changing the frequency of the electrical current. A powered conveyor with a belt is a simple conveyor to adjust the speed on Moving a product around curves. Curve style systems are available to maintain the proper product orientation while a product moves around the curve DISADVANTAGES – DON’T USE THEM IF YOU NEED: Accumulating products (i.e. for a buffer). Belt style conveyors can’t allow the products to nest up against each other (“accumulate”). If you let products pile up against each other, they will get damaged. You could also have problems with them pushing product off the belt. If you need accumulation, use a roller conveyor or overhead conveyor. Accumulation means buffering. Products that won’t slide or roll off the belt. A powered belt system requires the part to ride on the belt without sliding. If you need the parts to be held while on the conveyor, there are other alternatives. Consider a slat conveyor which can be fitted with tooling to hold the product in place. As the conveyor moves along the product rides in the tooling on the slats. To use the conveyor as a working surface. Belt style conveyors are made for transport, not for production operations on them. Use a slat conveyor or roller conveyor for these type of situations. DIFFERENT TYPES OF BELT MATERIAL CHOICES General purpose belting material Rough top belt – for extra grip on inclines, declines and products that might slide Higher chemical resistance – for best protection from chemicals Cut resistant conveyor belt material – for rough or sharp items like sheet metal or bricks. The extreme heavy duty belts are very strong High temperature conveyor belt. For parts coming out of hot presses, we have belt materials available. In some cases, belt conveyors can run through lower temperature ovens. STYLES AVAILABLE IN CUSTOM CONFIGURATIONS: De

Looking for "Belt Conveyor System" ?

Explore More Products